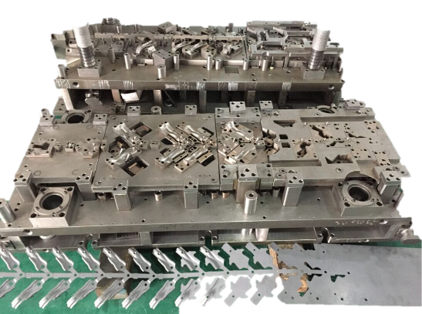

design, manufacturing, installation and maintenance of devices, presses, molds, dies and engineering changes.

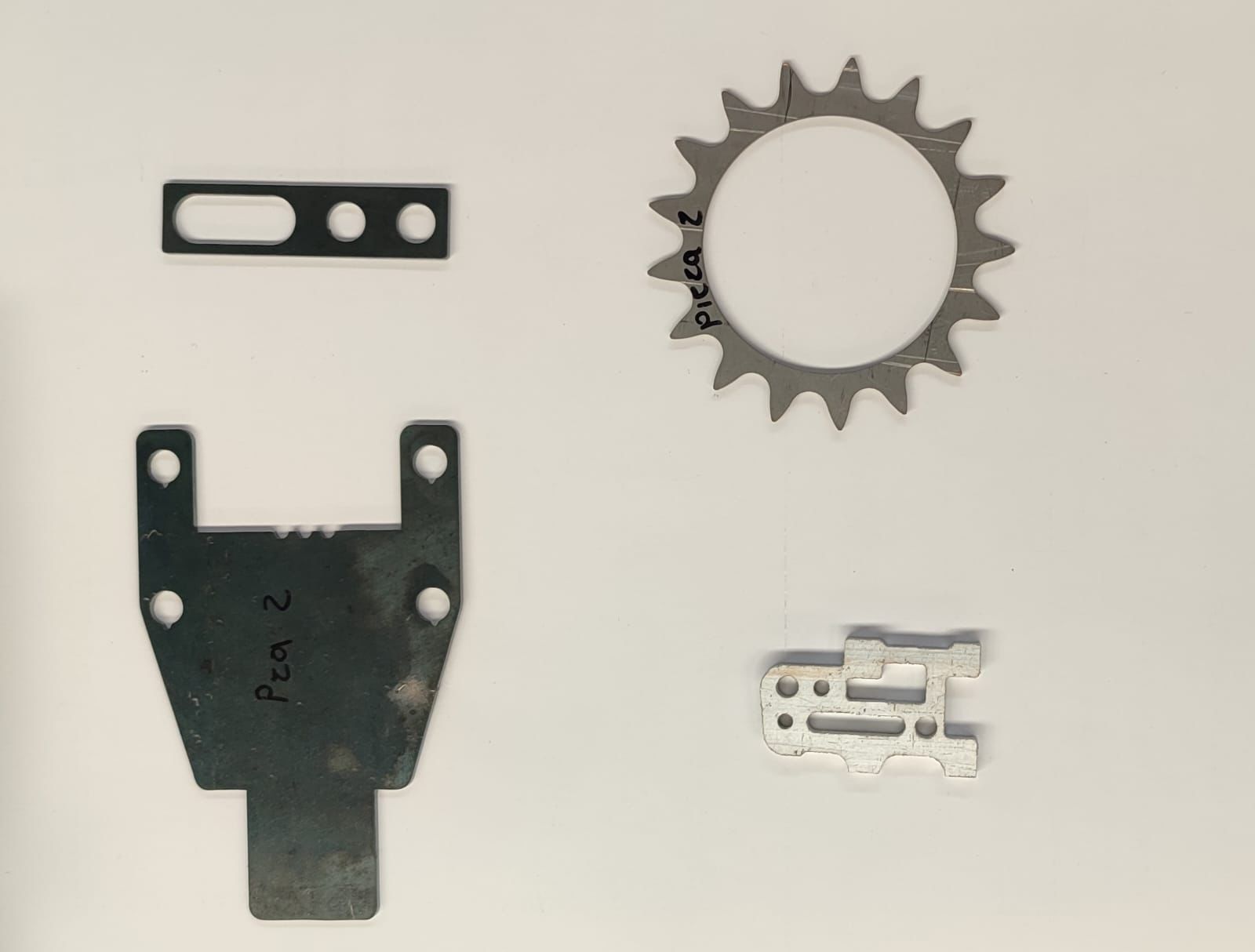

Production of stamped parts. Production of assembled parts.

We are a company that is dedicated to the design and manufacture of dies, as well as the die cutting of metal parts. Within our services we offer machining, laser cutting, consulting, corrective and preventive maintenance of dies, reverse engineering and manufacturing of control devices.

Satisfy the needs of our clients by exceeding their quality, cost and service requirements, through the continuous improvement of our processes, products and service in a safe and reliable work environment. Our technical and administrative staff has extensive experience in the metal-mechanical industry as well as in the die-cutting of automotive parts.

To be a company of excellence in the metal-mechanical area, through continuous effort to consolidate ourselves as the best option in the market

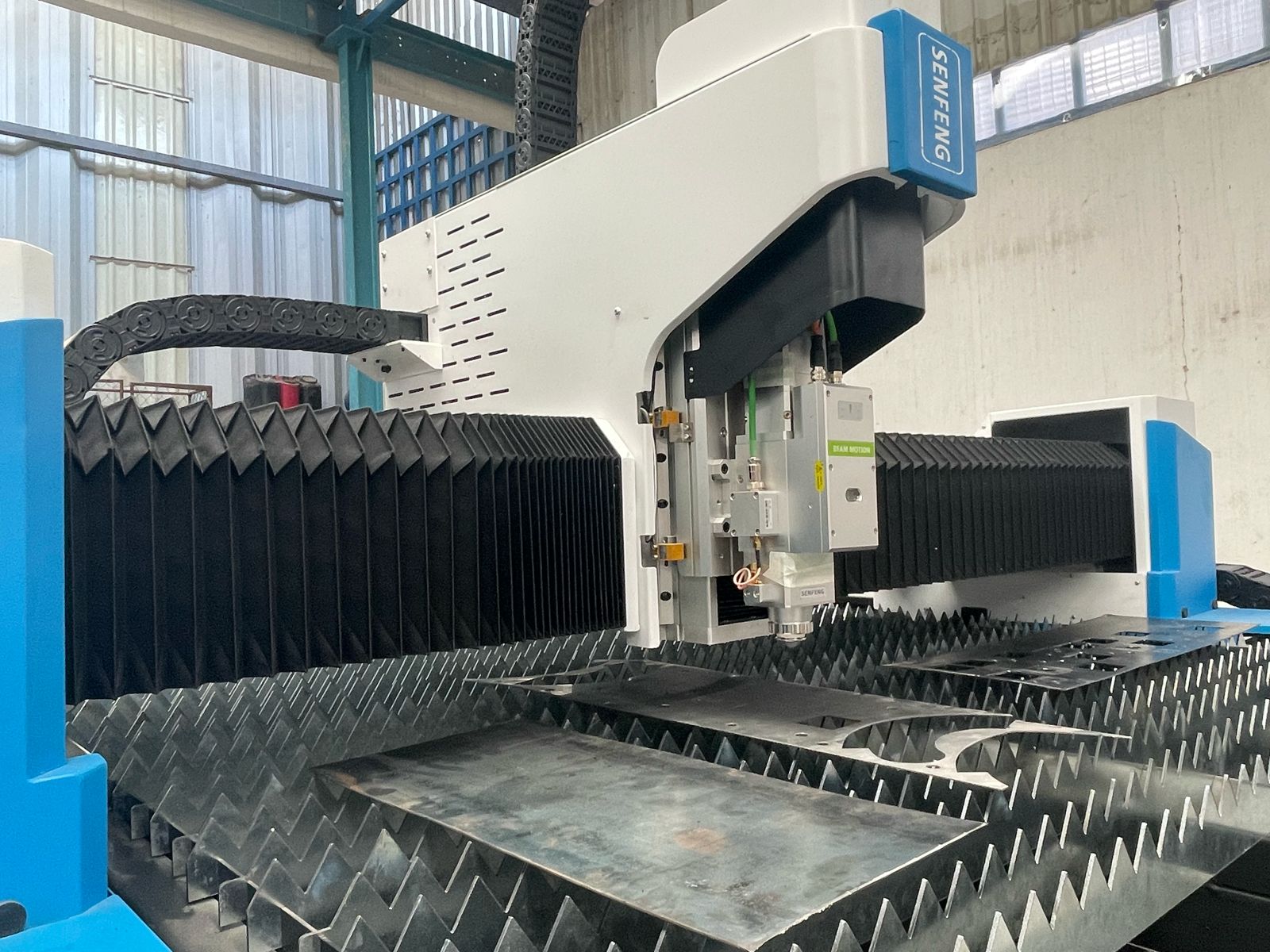

Our growth must occur based on the needs of our clients, which is why we have no problem investing in systems, machinery, equipment and, above all, in human resources, in order to fully satisfy the market requirements.

At DITROMEX we care about serving our customers. We offer advice for the optimization of operations, automation and implementation of quality systems.

Consultant services.

Trouble shooting and correction dies & molds.

Preventive and corrective maintenance

Manufacture and assemble of Automotive and Comercial industries.

Design changes to die toolings and checking fixtures. (Engineering changes)

Try out dies to presses.

CNC machining processes.

3D Scanner For Metrology and reverse Engineering.

Design & fabrication of sotf tools

Laser cutting

No matter where or what you want to build, we mobilize the right resources and experts to drive value and realize your project goals.

Certification ISO

Since